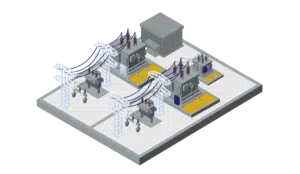

Predictive maintenance for substations

SIPP technology enables simple, reliable and safe digitalization of substations.

Environment-technology for Energy Companies

SIPP – Industrial IoT

SIPP™ has for a long time offered customers in the energy sector connected equipment that ensures the function of oil catch pits in substations. With the latest SIPP™ technology, customers are offered the opportunity to connect additional sensors, and safely use Gomero’s proven infrastructure to collect and analyze real-time data. This supports customers in the transition from traditional scheduled maintenance to condition-based and more predictive maintenance work.

SIPP offers a total solution that gathers and analyzes data from multiple sensors, and then transmits the outcome into customers’ existing systems. The unique SIPP-interface generates automated reports and protocols with full traceability, as well as alarms for crucial parameters. It also includes secure cloud storage of data, remote updates of software and telephone support.

Gomero Group AB (PLC) helps customers in the energy sector to long-term sustainable economic growth through the development of systems and services for predictive maintenance – an important strategic issue in the energy transition. With Gomero’s connected products, sensors and data analysis, we ensure that maintenance work can be optimized while meeting the requirements for cost efficiency and sustainability.

Gomero’s product SIPP™ is the market leader in Sweden and helps over a hundred customers in nine countries with digitalization of maintenance processes at substations. For customers, this means increased reliability, reduced costs and better opportunities to work more efficiently with their maintenance. Gomero’s customers include Ellevio, Vattenfall, Lede AS, Fingrid and Deutsche Bahn.

The group, based in Gothenburg, consists of two wholly owned subsidiaries, Gomero Nordic AB and Gomero Pty. Ltd.